Bin Whipping Solutions for Cleaning Silo & Bin Buildup

Powered by Premium Plant Services

Efficient Cleaning for Silos & Bins of All Sizes

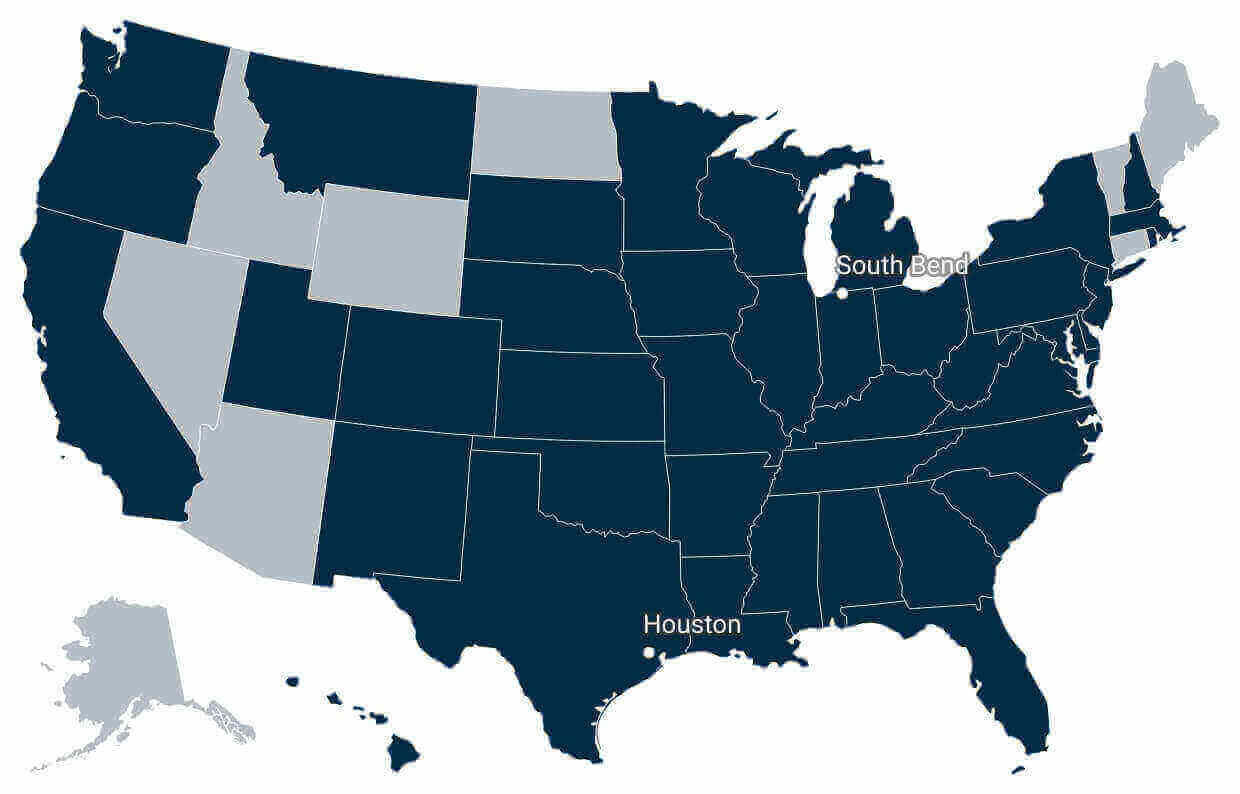

Bin whipping, powered by Premium Plant Services, is a proven method for removing hardened materials and resolving common challenges like buildup, plugging, bridging and ratholing in grain bins, silos and other storage structures.

Trained Premium Plant Services technicians utilize industry-leading equipment and expertise to help keep your storage facilities in pristine condition. Our innovative hydraulic system uses food-grade oil, ensuring a safe and contamination-free process.

How Bin Whipping Works

Bin whipping uses hydraulic tools to break up compacted material from the inside of a bin or silo. Operated remotely from the roof, this system eliminates the need for personnel to enter confined spaces, reducing the risk of engulfment, entrapment or other safety hazards.

The process is highly adaptable: material freed by the whip can be removed through standard bin functions, such as augers or vac trucks. A small access point at the bin’s bottom may be needed to ensure safe and efficient material flow before using a drill or whip.

Benefits of Hydraulic-Powered Whipping Tools

- Operate at lower speeds with higher torque for greater precision

- Configurable to match the size and shape of each bin or silo

- Accommodate diameters 50 feet and larger using multiple access points

- Support high-dust or explosive environments with intrinsically safe whipsets

- Operate remotely, eliminating confined-space entry risks and enhancing safety

Customizable Whipsets for Optimal Cleaning

Choose from a range of durable whipset options designed to address varying material densities:

Bronze Chain

Bronze Chain

Non-sparking and corrosion-resistant for sensitive environments

Star Knuckle

Star Knuckle

Nylon rope with ultra-high abrasion-resistant polyethylene knuckles

For greater efficiency, the dual-head system stabilizes the whip, spending more time attacking material instead of skipping over denser spots. It’s up to 40% more effective than single-head setups.

Advanced Silo & Bin Cleaning Solutions

When material bridges or plugs the outlet, bin drilling helps to create flow and facilitate whip navigation. Drill stems are added in sections to reach the bin’s bottom without contacting the sides or slope, preventing equipment damage.

Drill duration depends on the material’s density, quantity and height, with jobs ranging from one day to several weeks. Note: a small void must be created in the material before drilling begins to ensure effective operation.

Key Benefits of Bin Whipping

Safety

Safety

Eliminates confined-space entry, reducing the risks of falling, engulfment, and entrapment by keeping the operator outside the bin.

Versatility

Versatility

Handles bins and silos of all shapes and sizes, including those with complex configurations.

Efficiency

Efficiency

Dual-head systems and customizable whipsets ensure thorough cleaning in less time.

Industrial and Commercial Cleaning Expertise & Reliability

As part of the Premium Plant Services family, Polar Clean provides safe, effective and environmentally responsible industrial cleaning solutions for a wide variety of commercial and industrial cleaning challenges.

With deep experience, proven processes and training and certifications for working in conditions that include heights, confined spaces and the use of supplied air, the Polar Clean team gets the job done, safely, cost effectively and on time.

Contact Polar Clean to learn more about bin whipping solutions.