Fast, effective paint removal & restoration cleaning without water or chemicals

While dry ice blasting is specified in many commercial and industrial applications where a more delicate water-free touch is ideal, sponge blasting provides the benefit of slightly more abrasive force. Using reusable synthetic sponge pieces embedded with media of varying abrasion, sponge blasting provides what is still a softer touch, but with more abrasive options effective for applications like removing well-adhered paint in restoration settings and other applications where the introduction of water and other messy media is problematic.

Sponge blasting is also effective for dust suppression and can be used in combination with dry ice blasting for paint removal and paint preparation applications where more abrasive force is needed is some areas.

Reduce Power & Petrochemical Plant Repairs, Downtime

Sponge blasting is also effective for removing carbon buildup, dirt, fly ash, fouling and other adherents from power generation, ethanol and petrochemical facilities and equipment that requires a more abrasive approach than dry ice blasting.

Safety & Environmental Advantages of Sponge Blasting

Sponge blasting is safe for operators because it refracts/rebounds and suppresses dust by up to 90% compared with sandblasting. This prevents damage to nearby equipment and personal protective equipment (PPE) and enables its use in confined spaces where other blasting options are unsafe or impractical.

The sponge media that is filled with micro-abrasive particles is chemical-free, recyclable, and can be used up to 10 times. This makes sponge blasting a more environmentally friendly alternative to hydroblasting and sand blasting.

There are over 20 different types and sizes of grit that can be embedded into sponge particles, ranging from 0 to 150 microns (0 to 6 millimeters).

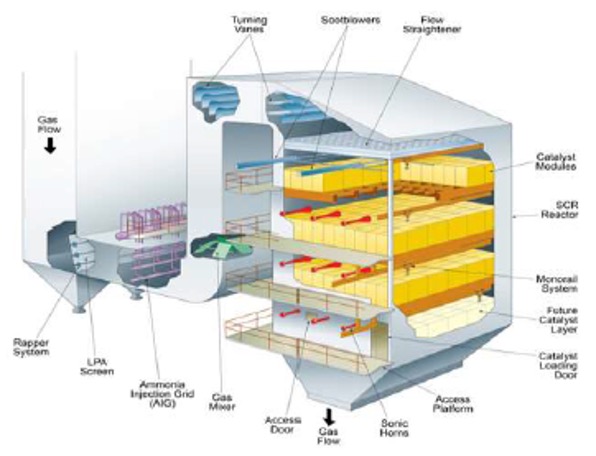

Power Plant Example: Sponge Blasting for Cleaning SCR Catalysts

Sponge blasting has proven highly effective for cleaning selective catalytic reduction (SCRs), saving power plants millions in repair and replacement costs in addition to reducing downtime.

Good flow and distribution, a good ammonia-to-NOx balance, and maximum catalyst surface area for NOx and mercury oxidation are key to achieving maximum SCR efficiency.

Sponge blasting does all three, removing hardened ash in ways that traditional hand-cleaning, vacuuming and vibration cleaning can’t – with less risk and at lower cost, especially when speed is factored in.

Sponge Blasting is Fast & Effective for…

- Steam turbines and rotors as a grit / sandblasting alternative

- Boiler stacks and chimneys

- Pumps, valves and gates

- Confined spaces and settings where the mess of sandblasting or slurry blasting is problematic

- Paint or coating removal that requires some abrasive force

- Historic restoration applications where adjustable force is required for delicate surfaces

- Hazardous material removal like lead paint where disposal and dust suppression are critical

Sponge Blasting Consultation & Quote

Sponge blasting is ideal for restoration cleaning, paint removal and SCR catalyst cleaning, among other applications, and our team has deep experience in using it to provide superior results for our customers across industries.

To learn more, call us at (855) 537-9423 or fill out the form below: we’ll discuss your situation and problems, estimate your costs, savings and ROI, and determine if a site visit is needed to finalize a quote.