Dry Ice & Abrasive Blasting for Paint Preparation

Paint preparation often requires the removal of years – or even decades – of grime, debris and rust, in addition to old layers of flaking and peeling paint.

Historical renovation work and the presence of lead-based paint bring additional complications to the process.

Dry ice blasting is often an ideal solution for managing these issues with its water-free, chemical-free blast of CO2 ice pellets that sublimate upon contact and create no added debris.

Painting and renovation contractors often specify dry ice blasting for jobs where the introduction of abrasive materials and water create a risk of damage to fragile surfaces as well as creating the need for extensive secondary clean-up and water reclamation.

How Dry Ice Blasting Readies a Surface for Painting

Using pellets of carbon dioxide (CO2) to blast away debris, rust, and loose paint, dry ice blasting can also be calibrated to deliver a feather-like application for cleaning fragile surfaces and around delicate equipment – even circuit boards and fuse boxes.

Three sources of energy transfer create the power behind dry ice blasting:

- The kinetic energy of the pressurized blast

- The microthermal energy of temperatures as low as -109 degrees Fahrenheit

- The sublimation energy of the CO2 pellets on contact

Specialized nozzles and processes also enable dry ice blasting professionals to clean hard-to-reach areas that might otherwise require tedious and time-consuming cleaning by hand.

Advantages of Dry Ice Blasting for Paint Prep

Dry ice blasting has numerous advantages over the alternatives for a wide variety of paint prep applications:

- Dry ice pellets evaporate (sublimate) upon contact so there is no residual clean-up required

- Professional dry ice blasters use engineered containment practices when necessary for the capture and removal of debris, including lead paint particles

- Dry ice blasting is non-toxic and approved for use in regulated food and health product facilities

- Dry ice blasting can be faster than other methods, cleaning up to 20 square-feet per minute

- Dry ice blasting can achieve a SP6 profile clean (commercial clean level)

- Dry ice blasting is effective around delicate surfaces and equipment

Paint Prep that Requires More Abrasive Blasting

Some paint preparation jobs require more abrasive blasting than dry ice can provide. While these methods carry some drawbacks and are more time-consuming – as slow as 1 square foot per minute – the removal of solid paint coatings or very stubborn build-up is usually a job for blasting that uses more abrasive media.

These methods require clean-up of residual water and abrasive material but are very effective, alone or in combination with dry ice blasting for paint preparation that requires the removal of multiple layers of intact paint.

Methods range from the most abrasive—crushed glass or glass beads—to the least abrasive methods, including those that use materials safe for use in food production areas:

- Non-toxic garnet blasting

- Chemical-free crushed glass or beads from recycled glass bottles

- Food-safe and environmentally friendly walnut shells and corn cobs

- Baking soda

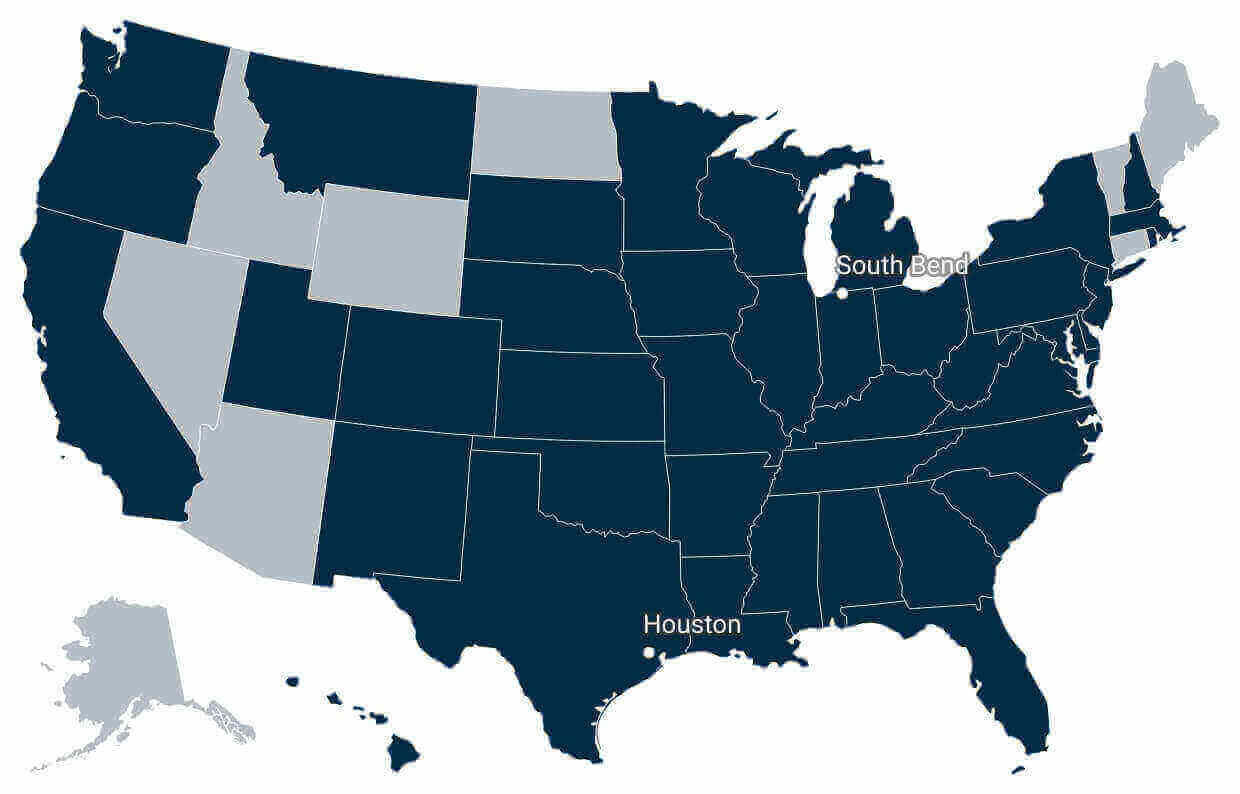

Why Polar Clean for Dry Ice or Abrasive Cleaning

At Polar Clean, our range of solutions for your industrial and commercial cleaning challenges come with the experience, professionalism and reliability of the Polar Clean team. Their credentials include training and certifications for the most difficult jobs, including those that involve working in high places, working with respiratory support, and working in confined spaces.

From salt mines to whiskey distilleries to petrochemical production facilities, power plants and historic renovation projects, our work is trusted by project and facility managers with no room for error.

Polar Clean solutions deliver safe, reliable, fast, and cost-effective results for businesses that can’t afford shortcuts. For more examples of our work, visit our before-and-after project gallery.

Bring us your cleaning challenges and we’ll provide you with a professional assessment that identifies the right blasting solution for your business.