Dry Ice Blasting for CNC Machines

CNC machines are something of a paradox; they marry two things that theoretically shouldn’t co-mingle but end up working together in perfect harmony: delicate electrical components and the hallmarks of heavy industry, including drill heads, lathes and grinding wheels.

Used in almost all manufacturing fields, CNC machines automate the work of creating nearly any part that can be thought up from metal, plastic, and wood.

The machines consistently yield two things: parts that are highly accurate and nasty messes that are very difficult and time-consuming to clean – a job dry ice blasting was made for.

Syrupy Slurries & Bacteria Breeding Basins

CNC machines use coolant or a combination of coolant and oil to lubricate, cool and flush away chips as they are created. The liquid – which is stored in “coolant basins” under the machine – is pumped through hoses, flooded or sprayed on parts during fabrication, and eventually recirculated back into the vat.

The process nearly always leaves a monstrous mess in its wake. The liquid and evacuated chips create a slurry that coagulates and can eventually harden. After being run, the sides of machines are often covered in a thick, tacky coating of the sludge.

Once grime accumulates inside the machine, gearheads can become clogged, which impedes gearwork function. Stuck, fractured bits of metal can become unintended saw blades.

Below the inner workings, the coolant basins pose a different, more dangerous threat. When improperly maintained and only cursorily cleaned, the vats become breeding grounds for harmful bacteria.

Regular cleaning is essential to ensuring the machines are bacteria-free, easy to service and operating at peak efficiency.

Tough Enough to Blast Grime & Delicate Enough to Dislodge Dust

The intricacy of the machines and complexity of the messes they leave behind pose some unique challenges when it comes to cleaning.

The slurry of liquid and chips can become semi-embedded into paint and onto parts and requires a relatively aggressive cleaning approach. But, because those parts often sit alongside sensitive electrical components, common forms of abrasive media blasting (like sand, soda, glass or water) cannot be used.

Luckily, there’s a perfect solution: dry ice blasting.

The method, which uses tiny pellets of CO2 to clean, is safe to use on sensitive electrical parts, including robotic heads, wires and controls. The machine’s blast can be adjusted to a gentle dusting, so it is both aggressive enough to remove sticky residue from sturdy surfaces and delicate enough to brush away grime from electrical parts.

And, unlike other methods of media blasting, dry ice sublimates on contact, which means no secondary debris is left behind. It effectively dislodges refuse caught between tiny gaps in bundles of wire without depositing additional residue.

The only truly safe alternative to dry ice blasting is manual cleaning, which is extremely labor intensive. The process generally involves several specialty products and tools and always requires a huge amount of elbow grease and time. Hand cleaning is also never as thorough as dry ice cleaning when it comes to cleaning out a machine’s multitude of nooks and crannies.

Grime Covered CNC Machines Make for a BIG Job

Polar Clean was recently called in to clean five massive CNC machines for a high-profile metal parts manufacturer. The dimensions of each machine? 8 feet tall, 10 feet wide and 100 feet long.

It was a huge job.

The machines were in desperate need of a thorough cleaning. The plexiglass windows where progress can be tracked were completely coated in a hardened slurry of liquid and metal. The wires and gears were also covered in grime.

At first, the manufacturer was hesitant to use any method other than manual cleaning on the multimillion-dollar machines. But after the Polar Clean team got started, they knew the machines were in safe hands.

Our team of four cleaned all five machines in two days – 2.5 times faster than manual cleaning. The client was thrilled by the efficiency of our team’s work that left the machines looking shiny and new.

Get Started Today

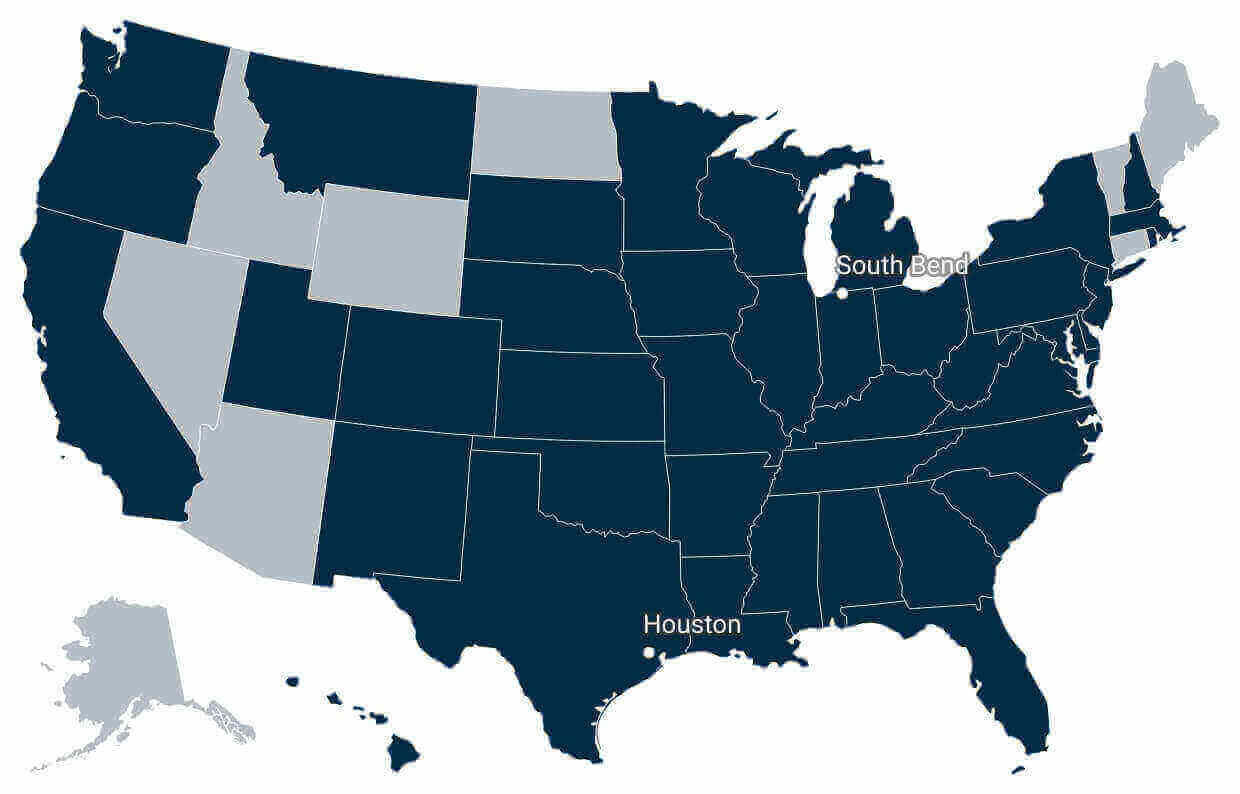

Polar Clean’s team of experts has extensive experience cleaning sensitive machines and parts with dry ice. Clients from a wide range of industries – including petrochemical, manufacturing, medical manufacturing and power plants – rely on the speed, thoroughness and adaptability of our dry ice blasting services.

If you have a complex cleaning job, reach out to our experts to schedule a dry ice blasting consultation or get a quote.