The Advantages of Cleaning SCR Catalysts with Sponge Blasting

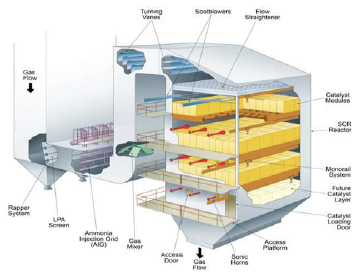

Good flow and distribution, a good ammonia-to-NOx balance, and maximum catalyst surface area for NOx and mercury oxidation are key to achieving maximum catalyst efficiency in a selective catalyst reduction (SCR) unit in power plants.

Sponge blasting does all three, removing hardened ash in ways that traditional hand-cleaning, vacuuming and vibration cleaning can’t – with less risk and at lower cost. Here’s how it works.

How Sponge Blasting Cleans SCR Units

Sponge blasting utilizes polyurethane foam media to safely remove potentially harmful, hardened ash from the surface and interior of the catalyst modules, with results that cannot be achieved by traditional methods.

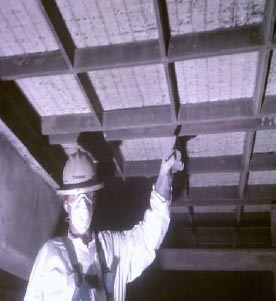

SCR Catalyst Before In-Situ Sponge Blasting |

SCR Catalyst After in-Situ Sponge Blasting |

Bottom of SCR Catalyst Layer Before In-Situ Sponge Blasting |

Bottom of SCR Catalyst Layer After In-Situ Sponge Blasting |

Cost of Reduction in Catalyst Activity

Using cost averages of between $800,000 (regenerated catalyst) and $1,200,000 (new catalyst – not including installation) with 192 modules per layer and a 25% loss over an 18-month outage cycle, sponge blasting can save $450,000 by recovering 60% of the loss—and costs significantly less than the savings:

| Layer | Investment | Loss at 25% | 60% Recovery |

| 1 | $1,000,000 | $250,000 | $150,000 |

| 2 | $1,000,000 | $250,000 | $150,000 |

| 3 | $1,000,000 | $250,000 | $150,000 |

| Total | $3,000,000 | $750,000 | $450,000 |

Traditional, hand-cleaning only recovers 20% of the loss, so sponge blasting saves an additional $300,000 in savings by comparison. And, as blockage percentage compounds over time (80% vs. 90%), the rate of erosion increases.

Costly effects of blockages:

|

|

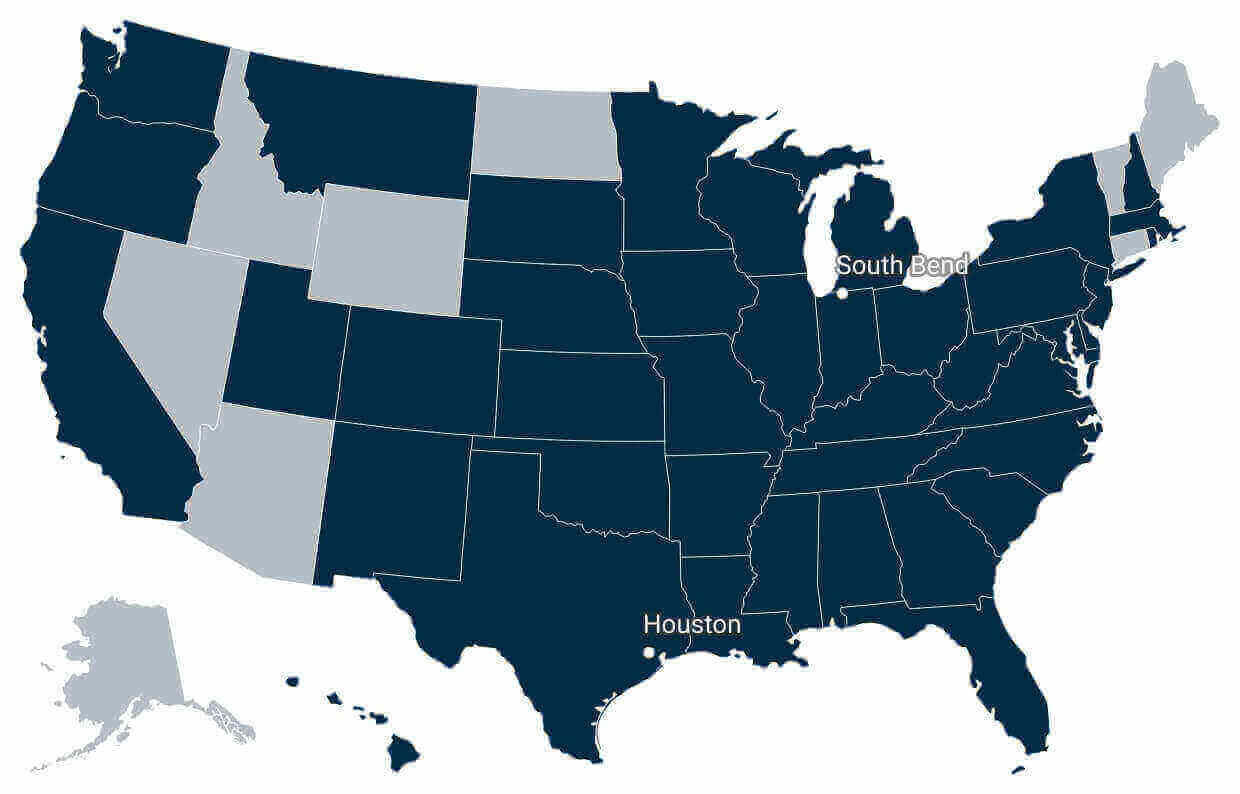

Sponge Blasting Service

While we’ve made our name in dry ice blasting, sponge blasting is a more abrasive alternative to ice with the added advantage of not refracting or damaging the protective equipment of the person spraying it.

Sponge blasting is ideal for SCR catalyst cleaning and our team has deep experience in using it to provide superior results for our customers.

To learn more, contact us: we’ll discuss your situation and problems, estimate your costs, savings and ROI, and determine if a site visit is needed to finalize a quote.

Contact us to learn more about sponge and dry ice blasting

All photos courtesy of ReNOx